|

@@

Fundamental Technology of Ball SAW Device for

Hydrogen Gas Sensor Established

The New Industry

Creation Hatchery Center research team of Tohoku University,

led by Professor Kazushi Yamanaka (Advanced materials

evaluation and sensing), has succeeded in a collaborative

effort with Toppan Printing Co., Ltd. and Yamatake

Corporation in prototyping the worldfs fastest wide-range

hydrogen gas sensor, with the support of US-based Ball

Semiconductor Inc.

The research focused upon a new phenomenon that was

discovered in relation to ultrasonic waves propagated on the

surface of spherical objects. The property of surface

acoustic waves (SAW) that make multiple roundtrips around

the sphere is specifically applied: in other words, the

amplitude and phase of SAW change while the waves pass

through a thin sensitive film with modified elasticity, due

to the adsorption of gas molecules.

This achievement was reported by 5 domestic newspapers; The

Daily Yomiuri(Jan.13), The Kahoku Shinpo(Jan.13),

Nikkan Kogyo Shinbun(Jan.17), Nikkei Business Daily

(Jan.18) and Kagaku Shinbun (Jan. 20).

@

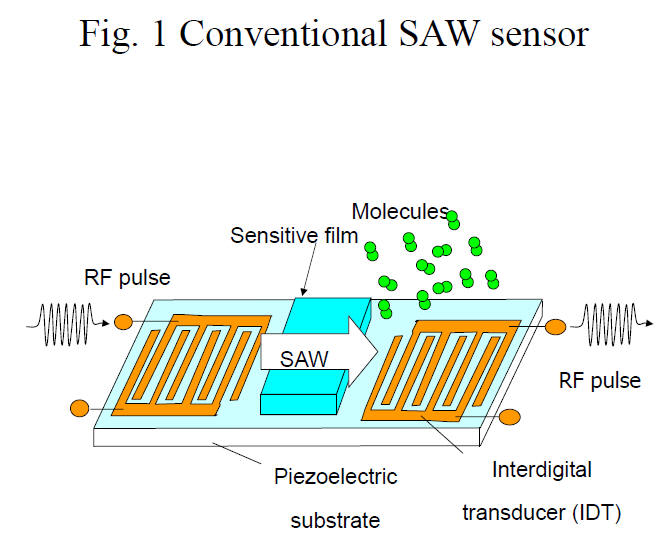

Hydrogen sensors (Figure 1) using conventional SAW are able

to detect hydrogen in concentrations ranging from 0.1% to

100%. The distance of propagation is limited, however,

because flat substrates are used for the device, and

sensitivity decreases as compared to the field-effect

transistor (FET) sensor.

@

@

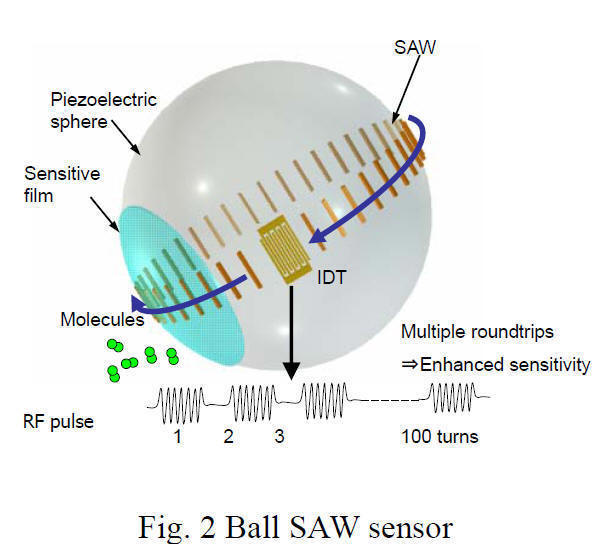

Based on the findings that SAW form naturally collimated

beams under certain conditions, are propagated through a

circular ring zone along the circumference of the sphere,

and make multiple roundtrips around it without attenuation,

the research team has developed a highly sensitive ball SAW

sensor (Figure 2) that can detect hydrogen concentration as

low as 0.001% applying this phenomenon.

In this experiment, increased signal strength through higher

precision device manufacture process and enhanced

compositional stability of the thin sensitive film adsorbing

hydrogen provided a rapid response time (1/50 vs.

conventional devices): four seconds at room temperature, and

two seconds at 130

C.

It is expected that the worldfs fastest wide-range hydrogen

sensor can be used in practical application as a flow

control valve for hydrogen stations. The team has also

developed a spherical SAW sensing/assessing device and

sensor module for other purposes.

As this sensor can be applied to a wide range such as gas,

liquid, temperature, and pressure, it may create a new

market in various fields including: sensors (hydrogen, CO,

pressure, etc.) expected to play an important role in the

safety management and the control of fuel cells;

environmental sensors for hormone disrupters, gases, odor,

etc.; and bio-sensors for protein chips.

The evaluation device and sensor module developed during

this project will be provided to universities, companies,

and research organizations both domestically and abroad to

call for far-reaching collaboration.

@

Back

@

Contact:

Prof. Kazushi Yamanaka

New Industry Creation Hatchery Center (NICHe)

Tohoku University

Tel:

+81-22-795-7357

@

@

|